How to Customise a Flatpack Wardrobe

Flatpacks are a fast, budget-friendly way to get great storage, and they’re more flexible than you might think.

DIY specialist and renovator Natasha Dickins of Little Red Industries shows how a few clever tweaks can help you fit standard-size units into a non-standard space, making them narrower or shorter to suit.

Tools and materials.

Make a unit narrower.

The key to making a flatpack unit fit a slimmer space is to trim all horizontal pieces to be the same width, working from just one side. Re-drill the holes with same-size drill bits, then assemble as normal with the supplied fasteners.

Calculate and measure the new width

Measure the space and subtract the thickness of the vertical side pieces (gables) for the final cut width of all horizontal pieces. We reduced this standard 608mm unit to a width of 520mm. The gables are 17mm thick, so the final width of the horizontals is 486mm.

Tip: Position two smaller pieces to allow for the thickness of the gables and simply mark the cut on the top or base piece.

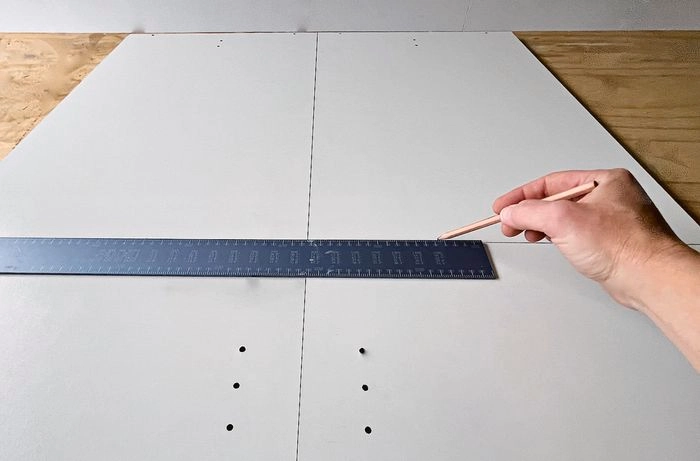

Mark the shelves

Use a combination square to transfer the cut line along all horizontal pieces, including the top, base, shelves, kickboard and any infills.

Tip: Only cut one side of each horizontal piece, working on the side that will be least visible when the unit is installed.

Cut along the markings

Clamp a straight edge (we used a length of pine) to trim with a circular saw, keeping the offcuts. Smooth away any breakout with 180-grit abrasive paper.

Tip: To keep the straight edge flat and to prevent the clamps from obstructing the saw, and to keep the straight edge flat, position the gables under it on either side, moving them from the path of the blade.

Transfer the cam holes in the shelf

Use the offcuts as templates and mark the centres with a combination square. Use a 20mm Forstner bit to drill in stages, checking the depth to avoid going right through. Test that the cams fit flush and flat.

Tip: If you don’t have a Forstner bit, drill right through the cam pinholes in the gable to secure the shelf from the outside with 40mm screws.

Assemble the unit

Join the factory edges of the top, base and shelf to the gable first. Before installing the screws in the remaining gable, use a 3.5mm bit to pre-drill through the existing holes and into the corresponding top and base pieces.

Tip: Use a screwdriver to install cams and cam pins; use a drill to install screws.

Cut the backing

Position the assembled unit on the backing to mark the excess, then cut with a circular saw or handsaw. Flip the unit to be face-down to reposition the backing with the laminate side facing in, securing with adhesive and the supplied nails. Always reinforce flatpack joins with a bead of adhesive along the raw edges before securing.

Tip: Work with the manufacturer’s markings and straight edges as much as possible.

Make a unit shorter.

Measure and mark

Check the height required, then position the gables together to transfer the measurement, working up from the base and marking across the inside face with a builders square.

Tip: Cutting from the base keeps the neatly finished laminated edging at the top.

Cut along markings

Working on a surface large enough to support the gables, clamp a straight edge to make the cuts with a circular saw, keeping the offcuts and smoothing away any breakout with 180-grit abrasive paper.

Drill holes to match offcuts

On the offcuts, check which holes attach the base and kickboard (these go right through), and clamp them onto the corresponding gables with the sides and base flush. Drill right through with a 5mm bit.

Assemble the unit

Position it on the backing piece to mark and cut to fit. Reposition the backing with the laminate side facing in, securing with adhesive and the supplied nails.

D.I.Y. tip: To move the position of a fixed shelf, simply remake the holes for the supplied fasteners in the gables and then install as normal.

Keep in mind:

- Wear safety equipment while using a drill or circular saw and always follow the equipment’s instructions.

- Paint colours may vary on application.